|

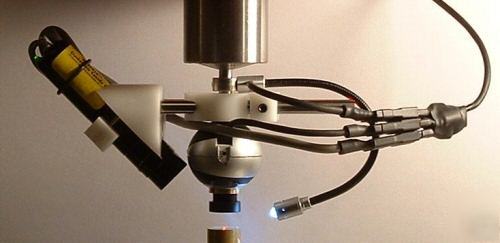

Full 3D pointing and measurement capability is achieved by combining our high concentricity cnCam-e camera with a precision-built thin line laser scanner. The resolution is 0.0004 in all directions and the XY concentricity is guaranteed to be within +/-0.0002 , U.S. Patent pending. The laser illuminates your workpiece at a 45 deg. angle effectively converting any Z differences in the field of view into X shift left or right from the center position. You achieve the calibrated Z reference position by aligning the laser line with the center mark (the on-screen pointer), as shown in the first picture. Our standard laser module (included) delivers uniform intensity straight lines of only 0.001 width. You can upgrade to a micro focus laser capable of drawing 0.0002 , see our store for details. Note that commonly used and inexpensive laser line generators deliver lines that are much, much thicker, i.e. 0.040 -0.080 or worse, and usually have Gaussian intensity distribution, often with line discontinuities, making them useless for precise measurements. Typical applications for the cnCam-3D include on-machine or in-process inspection and reverse engineering. Touchless by nature, the camera will work on all kinds of materials and can easily perform measurements on slopes and inside holes. It works in near infrared, too. Imagine not having to remove your workpiece from the machine and having CMM quality measurements performed directly on your machine.This is the power of the cnCam-3D. Extreme precision camera shank delivers perfect camera reinsertion capability. - a cnCam-e camera preset to 0.0004 resolution. - standard laser line generator, 0.001 line. - precision laser holder with a V block to accommodate lasers of diameter up to 1 - Platt blow molded case with foam insert - On-screen measurement software (see our store for software details). Delivery within 2-4 weeks ARO depending on your selection of the laser unit. We do not keep stock of expensive lasers. If you already own a cnCam camera (any model) you can upgrade to 3D by purchasing the laser holder and a laser module of your choice. You can think of the cnCam-3D as an extremely precise 3D probe installed in your milling machine's spindle in such a way that the active point of the probe is exactly (within 1/2 the camera resolution) aligned with the axis of rotation of the spindle. You use your cnc mill's position readouts to measure the position of the probe in reference to an arbitrarily selected zero point.Now, the probe allows you to take a snapshot of the vicinity of a known location and make on-screen measurements. This way the probe does not have to be moved exactly to the point of interest. More, it is possible to work with multiple snapshots taken at different locations and make measurements using points that belong to different snapshots. This way it is possible to measure large objects with full resolution of the camera, objects far bigger than the field of view. Our cameras provide two viewers. One is a real time video viewer with just a cross as the overlay, the other one captures ("steals") frames (snapshots) from the video stream, allows complex measurements, and displays measurement-related overlays. Both viewers are included in the price of the camera. The second viewer is called "on-screen measurement SW" and it can work with any TWAIN compatible camera or scanner. Measurement requires clicking on the image: 1 click - point, 2 clicks - distance, 3 clicks - diameter and center point of a circle, 4 clicks - angle (two intersecting lines). Typical applications for the cnCam include aligning the machine itself, aligning workpieces on machines, evaluating mill's performance (free running and under load), on-machine inspection, reverse engineering, etc.On-machine inspection and reverse engineering are performed on a point-by-point basis. Using a solid modeling software such as Alibre, SolidWorks, ProE, etc. the user is expected to draw a 3D model based on the collected data points. Once finished an .stl file can be generated for rapid prototyping or machining. This process works well for objects with a regular geometry and actually produces results much faster than a full 3D scan, especially for big objects where point cloud generation with high resolution (0.0004"=0.01mm) can take many hours. Note that good laser scanners usually have resolutions in the order of 0.005", i.e., we are 10 times better. If your object has an irregular geometry or you need an exact copy with all the imperfections at the surface the above process that usually works well for machining/inspection/reverse engineering would not serve your needs. You would need a point cloud generator/scanner. Note however that a point cloud generated by a scanner and imported into a 3D solid modelling software will not allow you to make any changes to the design of the part. Typically you end up re-designing your part around the point cloud anyway (there are however some sw packages targeted at the dentists that allow freehand additive and subtractive sculpting of the point cloud).At the $949.- level we do not provide any image recognition software that would build a point cloud and output an .stl file automatically. However, as a custom job, we can deliver full scanner software working with your mill provided that the mill can be driven with standard G codes. We have a new telephoto lens for the cnCam-3D that allows 3D resolutions down to 0.0002" (+/-0.0001") at a distance of 1.5". Ask for it when ordering the set. In addition to the 14-day no questions asked money back guarantee you are getting a standard 90-day warranty for parts and labor. (.0004" 3D camera cnc cmm machining reverse engineering was posted and is owned by: Minerva Gross) |

minerva_gross@chicagopartsnetwork.com (Minerva Gross) for more information.