|

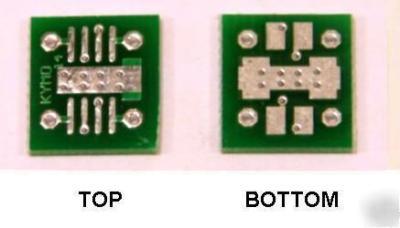

SOIC-8 to DIP-8 direct-to-socket converter Breadboard and experiment with SMT parts in a way never possible before. SUPPORTS IC'S WITH METAL THERMAL PADS This listing is for style #14, shown below Thermal pad: all types supported, 2-side stiched This is a BOTTOM solderd carrier. Pins are surface-soldered on the bottom of the PCB, and do not emerge to the top side (except for the corner pins). More unobstructed space topside for easy soldering of the IC Thermal lands under the IC for cases with exposed thermal pads Shorter and more direct traces from IC to pins, for high frequency integrity. #14 and #17 are bottom soldered. #15 and #16 are top soldered carriers (all thru-hole pins) but do not have the above features. Header pins are cutt off or shortened, leaving only a short stub for soldering (except for the corner pins). Corner pins will be soldered as usual, topside, and will keep the header anchored and aligned. See photos below. Remaining pins are surface-soldered on the bottom side, to the extra-large pads provided. Use minimal solder time to avoid melting the header frame. Use flux to get the solder flowing quickly. Above: female machined sockets can also be used, if available, by inserting short lengths of thin wire in them. Let the corner wires protrude through the PCB, and bend all other wires outward for surface soldering. Use sufficient solder to fill the cup of the machine socket. Industrial PCB assemblers use machines, not humans to place parts on a PCB. The solder paste is applied by silkscreening (printng like an ink) and melted by reflow systems. These systems only require IC solder pads as small as a tiny dot, and they can get the IC soldered in position every time with pinpoint accuracy. 1. Space where to put the soldering iron when heating the pad, while maintaining a distance of 1-2 mm from the IC lead. (You should not touch the IC lead with the iron tip directly.) (Smt to dip adaptors, soic-8 to dip-8 converter smd, #14 was posted and is owned by: John Clay) |

john.clay@chicagopartsnetwork.com (John Clay) for more information.