|

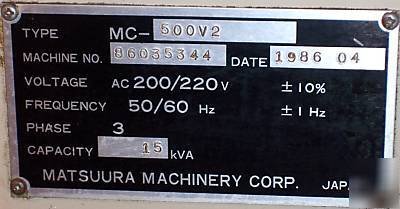

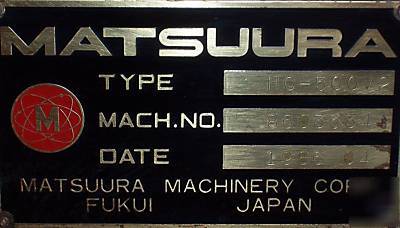

This listing is for a VMC (vertical milling center) / milling fabrication machine. * Seriers: Matsuura System MX-II (MXII) (MX-2) (MX2) * Model / Part #: MC-500-V2 (MC500-V2) (MC-500V2) (MC500V2) * Power: 200/220V / 50/60Hz / 3 Phase / 15KVA Capacity Here is some information from the manual... * MC-500V is of highly rigid bed-type construction. * Spindle headstock slides vertically along the two 85mm-wide guide ways, on the Z axis, driven by Yasnac transistor-drive DC motor. The mating face on the headstock is plated with Turcite for stick-slip free motion. It incorporates the main spindle, the spindle key-lock orientation system, tool holder retension system. * The spindle is drive by 3.7KW (continious) AC motor for the entire range of 40-4000rpm or 60-6000rpm. Spindle speeds are infinitely variable by direct rpm programming. The spindle speeds are commanded either automatically by tape or manually by MDI switches and key-baords. * The spindle nose taper is No. 35 (Matsuura Standard) * The spindle is supported by two sets of combination angular ball bearing at it's lower (taper) and by the double cylindrical roller bearings at its upper section for maximum percision and rigidity. * Automatic Tool Changer consists of the tool magazine carousel and the magazine shuttle and is installed on the left side of the column. The ATC system is driven pneumatically and by induction motor. The whole system is of very simple construction to insure trouble-free operation. * Tool Selection is by address codes, random selection, and the magazine carousel rotates in either direction, whichever is the shorter to the next tool. Thus quite speed tool change action is obtained. * The column is fixed to the bed with bolts. It has two 85mm-wide square guide ways for the headstock. The ways are hardened and ground. On the left side of the column the magazine carousel and the machine sequence control box are mounted. On the right side of the machine NC unit is mounted. * The counter-balance weight is accomodated inside the column to make the headstock motion smooth and accurate. * On the top of the column, the Z axis feed motor is mounted. * The bed supports the whole machine. At the bottom of the bed, the levelling bolts are provided for level adjustment of the machine. * The bed is with two 95mm-wide square ways on the Y axis, hardened and ground. The mating face on the saddle for the Y axis is plated with TURCITE for smooth motion. * The saddle is strong enough to support the full weight of the table work load, with two narrow square guide ways, 60mm wide, with the DC drive motor mounted at the right to drive the X axis. * The table is 1165mm long and 500mm wide, with five T-slots arranged longitudinally. It travels along the guide ways of the saddle on the X axis. * The table is groove around its inside periphery for coolant which will be drained from the drain hole at the rear section of the table. * The pneumatic unit supplies the compressed air to the spindle clamp/unclamp mechanism and ATC magazine cylinders. The unit reduces the pressure available from the compressor in a shop to the level required for the operation. (6 to 9.5 kg/cm2 to 5kg,/cm2) * It is located at the rear left of the column. Main Operation Control Panel * The pendant type panel which has all the switches, buttons and display system built in is conveniently located at the right front section of the machine. * They control the spindle drive DC motor and axis drive motors and are mounted at both sides of the column. * Coolant unit consists of coolant tank, pump, hoses and coolant nozzles. Coolant tank is installed at the front side of the bed and collects the coolant. Tank capacity is 70 litres. * Coolant pump is installed on the top of the coolant tank. * It is installed at the lower left of the column and supplies lubrication oil to each slideway, ball screws, ball screw bearings in fixed quantity at fixed intervals. * Table Work Area: 380 x 865mm (14.96" x 34.06") * Table T-Slots: 18mm x 3 (11/16" x 3) on 100mm (4") centers * Work weight on table: 250kgs (550lbs) * Longitudinal (X) Axis: 510mm (20") * Cross (Y) Asix: 360mm (14.1") * Vertical (Z) Axis: 450mm (17.7") * Distance from table top to spindle end: 150-600mm (5.9" - 23.622") * Distand from spindle center to column guideway: 410mm (16.1") * Spindle Nose Specification: Matsuura Standard No. 35 * Spindle Speeds Available: * S: 4 digit direct rpm input * Spindle Orientation: Standard (Electrical) * Rapid Traverse - X/Y: 15000mm/min. (590") * Rapid Traverse - Z: 12000mm/min (472") * Cutting Feedrate By Tape: 1-5000mm/min (0.1 - 196.8in/min) * Main Spindle Motor (AC Frequency Motor) : AC 3.7/5.5 Model EEVA-5IKM * Coolant Pump Motor: 0.25KW, 2-Pole, 3-Phase * Lubrication Pump Motor for Slideways: 10W, 4-Poles, 3-Phase * Axis Feed Motors (X/Y/Z): 0.85 / 0.85 / 1.1 KW * Tool Selction: Random by address code, bi-directional rotation of magazine. * Tool Holder Specification: Matsuura Standard * Pullstud Specification: Matsuura Standard * Max. Adjacent Tool Diameter: 76mm dia. x 20 Tools * Max. Tool Weight: 6kgs * Max. Tool Length: 250mm * Machine Height: 2569mm * Required Floor Space: 2990mm (Wide) x 2290mm (Deep) * Machine Weight, With NC Unit: 3600kgs (7940 lbs) * AC200/220V +/- 10%, 3-Phase * 50/60Hz +/- 1Hz, 15KVA * Except above, a transformer is required. Check out the picture for more information. Feel free to ask any questions. WANT TO REACH ME BY PHONE? Feel free to call me (Trent) toll free (***) 972-1346. * AZ to NV/UT/NM/CO - $800 (Matsuura MC500V MC500 knee vertical mill vmc w/fanuc was posted and is owned by: Katheryn Bender) |

Katherynbender@chicagopartsnetwork.com (Katheryn Bender) for more information.