|

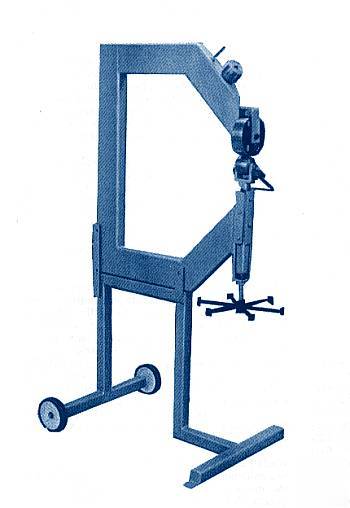

bounce, yer money order will get lost in the mail and yer dog won't come home. click on our "Contact Us" icon above for the quickest response to your questions. MAKE ENGLISH WHEEL FOR 3D SHEET METAL CURVES MAKE ENGLISH WHEEL FOR 3D SHEET METAL CURVES MAKE ENGLISH WHEEL FOR 3D SHEET METAL CURVES MAKE ENGLISH WHEEL FOR 3D SHEET METAL CURVES MAKE ENGLISH WHEEL FOR 3D SHEET METAL CURVES MAKE ENGLISH WHEEL FOR 3D SHEET METAL CURVES MAKE ENGLISH WHEEL FOR 3D SHEET METAL CURVES It takes an English Wheel to put a crown on an otherwise flat panel. Either that or a whole lot of carefully controlled pounding with a hammer and dolly. The English wheel is a lot easier to use but they're expensive! Around $5,000 unless you build one of the 4 Dave gives you plans for with his book. Doing it yourself with about $100 worth of materials you'll produce 3D curved panels just like the expensive machines the pros use! Here's Dave himself to tell you about his book . . . "The English Wheel, sometimes called the wheeling machine, is a simple non-powered machine for forming large radius bends in sheetmetal. It can form simple bends or compound shapes, i.e. domed or crowned panels. It was apparently developed in England at about the turn of the century by "panel beaters" who were in need of a more rapid and repeatable method of forming complex shapes in sheetmetal than had been available by hand methods. For limited quantities of panels where extensive production tooling is not warranted, it remains a valuable tool. "The English Wheel is quite rare and not to be found in but a few shops. After thirty years as an automotive hobbyist, I personally have only seen one English Wheel besides the one which I built for my own use. They are available commercially, but the costs are well beyond the typical hobbyist's budget. "In my own activities as a hobbyist, I have done quite a bit of body repair and restoration. From my own experience, I can testify that trying to form broad radius bends and/or crowned shapes by hand is extremely difficult. I have resorted to a number of round-about methods to attempt to imitate true crowned shapes at times. My own attempts to use shot bags, hammer/dolly techniques and the like have been very time consuming and painfully crude. As a result of this frustration, I began first to daydream, then to calculate, draw plans, and finally build my own English Wheel. "I have had my English Wheel built for most of a year now and have found it to be simple to use, effective in forming low crown panels, and much reduces the time needed to make usable patch panels. "I have attempted not only to provide complete plans for four different size English Wheels, but also to provide information on how to tailor the design to permit substitutions of materials and/or to confidently build a different size machine. The design calculations are also provided to allow the reader to assure himself that the designs given will work prior to committing the time and money involved in building an English Wheel. "I have written this material with the expectation that a commercially available Wheel is too expensive for the reader (as it certainly is for the writer). I am aware of four commercially available Wheeling Machines. Three of them are quite large and one of them is a bench machine. The bench machine for, 'limited size shops and smaller jobs'costs approx. $2400", has a 5" diameter by 3/4" wide upper wheel, 3 different 1" diameter by 13/16" wide lower wheels, and weighs "well over 100 pounds." This machine is described as "perfect for removing dents, smoothing hammer marks and welds." "The larger machines ranged in price from $4,600 to $5,400 in 1989 and have about the same capacity as the 44" machine in the book and they weigh well over 1,000 pounds! "Weight is an advantage only in that it helps keep the machine in place as workpieces are pushed back and forth through it. This much weight is definitely not needed for strength. There are numerous possible structural shapes which can be fabricated to form just as strong a Wheel at much lower weight. Since steel is sold by the pound, a lighter machine is cheaper to build. If additional weight were desired, there are several ways to dead weight the machine with much cheaper materials than steel. Another way to achieve stability with a lighter machine is to attach it to a bench, wall or post." You get the 40 page book of how to instruction on building and operating an English Wheel together with 4 11" X 17" sheets of plans for building 12", 24" 34" and 44" machines! Soft cover 8 1 /2" X 11" 40 pages. Visit my Marketworks Gallery! Power Tools for Power Sellers! Phone: (***) 744-4449 M-F 9:00 to 4:00 Pacific Standard Time This item has been seen by alt people! (Make english wheel for 3D sheet metal curves was posted and is owned by: Marshall Martinez) |

Marshallmartinez@chicagopartsnetwork.com (Marshall Martinez) for more information.